One of our friends has a life preserver bag that has seen better days. The bag is mounted to the aft rail of his boat. In the event it's needed, the person at the helm can quickly reach the encased life preserver and hurl it at the victim in the water.

One of our friends has a life preserver bag that has seen better days. The bag is mounted to the aft rail of his boat. In the event it's needed, the person at the helm can quickly reach the encased life preserver and hurl it at the victim in the water.

The situation here is the original bag shows signs of degradation and the attachment straps were failing - hence the unit was typically stored in a locker rather than mounted on the rail - resulting in a potential safety consideration. Therefore, the question at hand, was there anything we might do to help out?

Sure, let's make a bag from matching Sunbrella used elsewhere on is boat to make a new bag that would encase the original bag! I apologize, I forgot to rotate this picture.

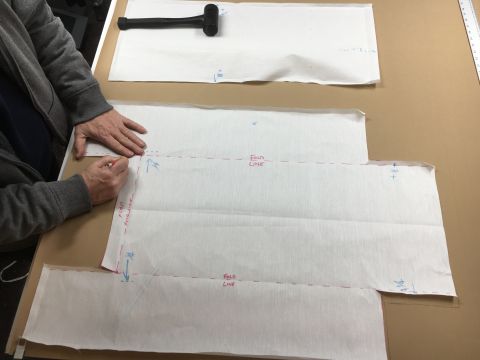

While I can't speak for Alan, I happen to have some work experience bending sheet metal and those skills came in really handy with this project. Upon examination of the original bag it appears to have been made from two pieces of material cut into intricate shapes and folded together - just like sheet metal! Mentally unpacking the bag to imagine the lay flat version, including additional material for making bends, is a skill seldom taught today as this type of work is now relegated to those who know how to use a computer but, I'll admit it, I'm old, but as feeble minded as I am, I can still go old-school on occasion! Pictured here is the basic layout of the two-piece pattern of the material needed to form the enclosure.

With the dimensioned drawing of the parts in hand, we transferred the artwork to muslin for a pattern that we were able to mock up using a few staples. As a novice, this step is always a good option because it gives you an opportunity to identify things you may have missed. As you might note in the image below, there are a couple of blue arrowheads indicating a need to increase the width of the mid-section by a slight amount. When satisifed with the pattern we transferred it to the Sunbrella fabric. Regarding material costs, muslin is under $2 per yard but Sunbrella runs in the neighbood of $20-30 per yard! We like to make mistakes on musiln.

After the pattern outline has been drawn on the Sunbrella, Alan cuts the fabric with a hot knife to A) separate the fabric and B) to prevent the raw edges of the fabric from unraveling. Sunbrella, like similar synthetic products, is made of acrylic fibers woven together to form a web of material. Thus, when heated it will melt at temperatures around the boiling point of water. Which raised the question, what would happen if you put Sunbrella in boiling water!!!? Could it be formed into specific shapes? Hey, this might be something for my students to experiment with!

All that remains to make a the enclosure is for Alan to sew the bag together. He's pictured here using Brutis, the Sailrite Professional sewing machine, a unit designed specifically for heavy flat work like canvas and sails. The existing unit fits nicely into the new bag and our friend is a happy camper!