In today’s world of instant information via the internet you would think a quick search would result with the information you are looking for. When you try to find something about an almost 200 year old sewing machine it is not on the side of the Super Information Highway. I would say it is more like information cave exploring. Some of it is out there but you need to dig for it. Go ahead try finding “Thread path for Standard Treadle sewing machine”. Did you realize the Singer Company almost bought up every sewing machine company there was?

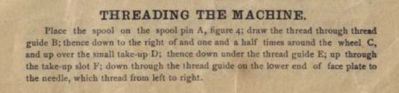

So back to the search, as I said it was buried. I finally found a person with a similar machine via Pinterest, noticed they had posted the picture on a forum about vintage sewing machines, so I joined the forum. I posted my question and a member pointed me to a section on the forum that had had a PDF of the original manual. Holy Cow, which is just what I needed. After threading it the correct way I was able to sew two pieces of fabric together. It did take a little more practice at the treadle part though.

It sewed Ok but still not quite right, so I thought I would have Russ come and look at it. After all he now has two professional machines. After some more test runs he thought we needed more bobbin tension. To adjust this you need to make very, very small turns on a tiny, tiny screw located on the bobbin case. I did mention I unburied the machine in my basement filled with other stuff. So Russ was trying to adjust the tension when I hear, Oh s(*@. I turned and said “What happened”,  “I dropped the screw” Russ said with a troubled look. So after about an hour we finally found it with the aid of a good magnet. All we had to do is but it back in. After another search on the floor we decided we should move to a place where the light was better and the floor was not so available. Well after about another hour of trying to reinstall the screw we finally accomplished the task. Unfortunately after all this work we were still not able to tighten the tension any tighter. The bobbin spring is bent too much. Back to the forum to see if I can find a 200 year old bobbin case, I am sure someone has a few laying around.

“I dropped the screw” Russ said with a troubled look. So after about an hour we finally found it with the aid of a good magnet. All we had to do is but it back in. After another search on the floor we decided we should move to a place where the light was better and the floor was not so available. Well after about another hour of trying to reinstall the screw we finally accomplished the task. Unfortunately after all this work we were still not able to tighten the tension any tighter. The bobbin spring is bent too much. Back to the forum to see if I can find a 200 year old bobbin case, I am sure someone has a few laying around.

So all this because I wanted to try thread painting and possibly using a treadle machine to do it. So I will just use the White sewing machine to get started. Stay tuned, I have to get some new thread.